Description

Single acting actuator is also namely pneumatic spring return actuator. Firstly, it converts the input air pressure signal into a 90 degree rotary travel signal. And then output in the form of torque. Single acting pneumatic actuator not only small in appearance, but also high in performance. There is a spring return device in pneumatic rotary actuator. Therefore, when the pneumatic valve loses the continuous supply pressure of the air source, the valve will automatically return to the original state of the valve under the counter force of the spring.

The application of spring return pneumatic actuator. We usually use it together with rotary valves, such as ball valves, butterfly valves, plug valves, air valves, etc. Because of the different working conditions and environments, it can divide this actuator into two types. One is normally open pneumatic actuator. And another is normally closed pneumatic actuator.

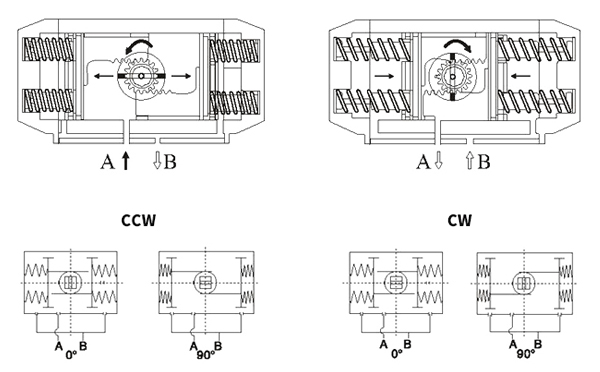

The working principle of spring return actuator

How does a single acting actuator work? Firstly, compressed air enters from port A. So it makes the left and right pistons move to both sides. Besides it squeezes the spring. The output shaft rotates counterclockwise. At this time the valve opens. Finally, it discharge the air from port B.

When there is no air or electricity, the two pistons move to the middle due to the action of the spring. So output shaft rotates clockwise. At this time, the valve is closed. Finally, it discharge the air from port A.

Specification of single acting spring return actuator

Specification model: AT-SR single acting pneumatic actuator;

Actuator rotation angle: 90°, and it can adjust -5 to +5 degrees from both ends;

Applicable air source: 0.2~0.8MPa;

Air source interface: accord with NRMAR standard;

Action form: pneumatic spring return actuator;

Ambient temperature: standard type -20℃~+80℃;

Outer casing material: muti-layer aluminum alloy.

Accessories available: such as solenoid valve, electric positioner, limit switch, filter, hand-operated mechanism.

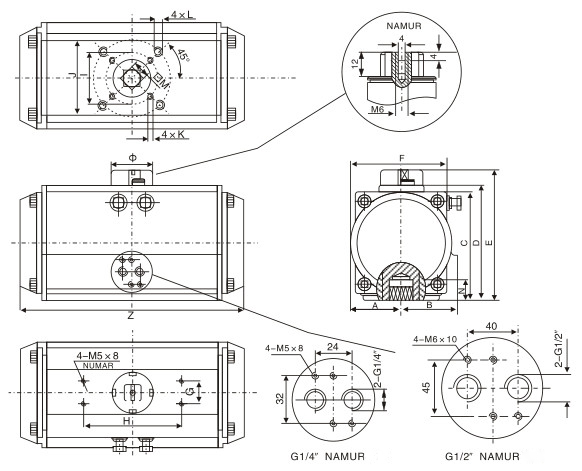

The dimensions of spring return pneumatic actuator:

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | Z | Φ | Air Source Port |

| SR-52 | 30 | 41.5 | 65.5 | 72 | 92 | 65 | 30 | 80 | Φ36 | Φ50 | M5*8 | M6*10 | 11 | 14 | 147 | Φ40 | NAMUR G1/4″ |

| SR-63 | 36 | 47 | 81 | 87.5 | 107.5 | 72 | 30 | 80 | Φ50 | Φ70 | M6*10 | M8*13 | 14 | 18 | 168 | Φ40 | NAMUR G1/4″ |

| SR-75 | 42 | 53 | 94 | 99.5 | 119.5 | 81 | 30 | 80 | Φ50 | Φ70 | M6*10 | M8*13 | 14 | 18 | 184 | Φ40 | NAMUR G1/4″ |

| SR-83 | 46 | 57 | 98.5 | 108.7 | 128.7 | 92 | 30 | 80 | Φ50 | Φ70 | M6*10 | M8*13 | 17 | 21 | 204 | Φ40 | NAMUR G1/4″ |

| SR-92 | 50 | 58.5 | 111 | 116.5 | 136.5 | 98 | 30 | 80 | Φ50 | Φ70 | M6*10 | M8*13 | 17 | 21 | 262 | Φ46 | NAMUR G1/4″ |

| SR-105 | 57.5 | 64 | 122.5 | 133 | 153 | 109.5 | 30 | 80 | Φ70 | Φ102 | M8*13 | M10*16 | 22 | 26 | 268 | Φ46 | NAMUR G1/4″ |

| SR-125 | 67.5 | 74.5 | 145.5 | 155 | 185 | 127.5 | 30 | 130 | Φ70 | Φ102 | M8*13 | M10*16 | 22 | 26 | 301 | Φ46 | NAMUR G1/4″ |

| SR-140 | 75 | 77 | 161 | 172 | 202 | 137.5 | 30 | 130 | Φ102 | Φ125 | M10*16 | M12*20 | 27 | 31 | 390 | Φ60 | NAMUR G1/4″ |

| SR-160 | 87 | 87 | 184 | 197 | 227 | 158 | 30 | 130 | Φ102 | Φ125 | M10*16 | M12*20 | 27 | 31 | 458 | Φ60 | NAMUR G1/4″ |

| SR-190 | 103 | 103 | 216 | 230 | 260 | 189 | 30 | 130 | Φ140 | M16*25 | 36 | 40 | 525 | Φ60 | NAMUR G1/4″ | ||

| SR-210 | 113 | 113 | 235.5 | 255 | 285 | 210 | 30 | 130 | Φ140 | M16*25 | 36 | 40 | 532 | Φ60 | NAMUR G1/4″ | ||

| SR-240 | 130 | 130 | 264.5 | 289 | 319 | 245 | 30 | 130 | Φ165 | M20*25 | 46 | 50 | 602 | Φ60 | NAMUR G1/4″ |

Single acting pneumatic actuator seletion

Firstly, determine the torque required to open and close the valve. When selecting spring return actuator, it must add to the torque. For example, for water vapor or non-lubricated liquid medium, increase the safety value by 25%. Secondly, for slurry liquid medium, increase safety value by 30%. Thirdly, if dry gas medium, increase safety value by 40%. Then for granular powder medium, increase safety value by 60%. Finally, for clean, low-friction lubricating medium, increase safety value by 20%.

For example, close a butterfly valve that requires a torque of 100Nm. Besides the air source pressure is 0.5MPa. At the same time, it is dry gas medium. Because of safety factors, it needs to increase safety valve by 40%. Immediately afterwards, check the output torque table of single acting spring return actuator along the column (0°) vertically. As a result, find that the similar torque is 145Nm. Finally, look for its number to the left along the line and select SR-125 actuator.

Spring return vs double acting actuator

Pneumatic actuator is the executive part of the control valve. We use it to control the opening and closing of the valve. Pneumatic rotary actuator has two types. One is single acting pneumatic actuator. And another is double acting actuator. So what is the difference between them?

Firstly, there is a return spring in the single-acting pneumatic actuator. For example, it forms a single-acting pneumatic ball valve with the ball valve. Moreover, it can automatically reset when there is no compressed air. Therefore, single-acting pneumatic ball valves should be used in key process control positions. Because it can form an interlocking control with the solenoid valve to cut off the pipeline in time to ensure the safety of production equipment.

On the contrary, there is no return spring in the double-acting pneumatic actuator. When there is no compressed air, it stays in place. Therefore, it cannot make actions that are conducive to process safety. So it is applied where the state of the control switch is not important. When the air source fails, the opening or closing of the pneumatic ball valve will not adversely affect the control system. At this time, it can use double acting pneumatic ball valve.

In short, if you need to automatically reset the valve in the case of loss of air, choose spring return pneumatic actuator. On the contrary, if you don’t need it, choose a double-acting actuator. In addition, there are no springs for double-acting cylinders. Therefore, the cost is lower than that of a single-acting actuator.

Characteristics of single action actuator

1. Firstly, only the opening action is driven by air source. But the closing action is spring return.

2. Secondly, only one end input (exhausts) air. Moreover, the structure is simple, and the air consumption is small. Not only acts quickly, but also reacts quickly.

3. The single acting actuator undergoes hard oxidation treatment. So it’s not easy to leave scratches.

4. The end caps are painted firmly. Therefore, it’s not easy to fall off.

5. The materials of all screws are SS304 stainless steel. So it’s very durable.

6. Further, the air supply hole conforms to the NAMUR standard. Thus, it’s convenient for the direct installation of the solenoid valve.

7. The inside of the spring return actuator is a rack and pinion. Because the output shaft and pinion gear are an integral structure, it can achieve the most accurate rotation angle.

8. The material of the return spring is high-strength alloy steel. So it has stable and reliable mechanical properties. As a result, it has significantly enhanced fatigue resistance and impact resistance.

9. The seal ring adopts the permanently lubricated nitrile rubber O-shaped seal ring. Thus,it doesn’t need to be relubricated under normal operating conditions.

10. Single acting actuator not only has a long service life, but also has a wide applications.

11. In addition, spring return actuator has good adaptability to the working environment. Especially in flammable and explosive occasions, it is superior to electric actuators.

12. Stroke adjustment: standard structure rotates at 90°C. In addition, there is an adjustment range of +/-5° at both ends.

Reviews

There are no reviews yet.