waterslide-transfer-decal-paper

Introduction of Water Slide Transfer Decal Paper

Waterslide decal paper is namely water transfer paper. Many objects, such as ceramics, wood, etc., are difficult to print directly for decoration due to their shape or material. But it can be water transfer decal paper can achieve it. As the professional waterproof DIY water slide decal paper manufacturer, we supply best waterslide transfer paper. Water transfer printing technology uses water as the transfer medium to transfer printed patterns to various objects. So Water transfer printing paper has wide application for ceramics, mugs, glass, helmet, candles, plastic models, tattoo, wood, bicycle, marble, nail art, etc. It can be divided into clear waterslide paper and white decal paper.

The Types & Specification of Waterslide Paper:

Types of decal transfer paper: inkjet waterslide decal paper (printable for inkjet printer), laser water transfer paper (printable for laserjet printer), silk screen printing water paper;

Paper size: A3(297*420mm or 11×17 inches), A4 (210*297mm or 8×11 inches), 390*540mm, 500*700mm, 600*800mm, etc;

Paper weight: 160gsm, 170gsm, 175gsm, 180gsm, 185gsm, 200gsm, etc;

Decal paper application: mugs, ceramics, glass, helmet, candles, plastic models, wood, plastic, nails, tattoo, guitar, etc;

White base decal paper: there print white base ink. Suitable for black or dark-colored items. Its purpose is to conceal the background color or shading of the product itself. So this can make the pattern clearer.

Clear (transparent) decal paper: suitable for crystal, glass, ceramics, white or light-colored items. It can reveal the background color and shading of the item itself.

Package size: A4 paper (20 sheets per plastic bag, 50 bags per carton);

How does water transfer paper work?

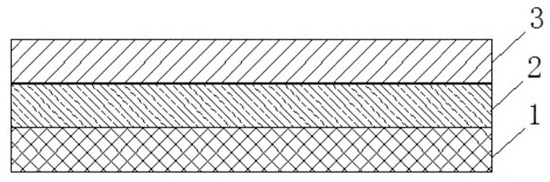

Here introduce the working principle of decal paper. Water slide decal paper is a transfer material acting as an intermediate carrier in water transfer printing technology. And water decal paper usually has the three layers structure as follows, such as lower layer (base paper), middle layer (water-soluble glue layer) and top layer (pattern layer). In addition, there is usually a protection layer (film) on the pattern.

Firstly, print the pattern on the water transfer paper. Secondly, cut the patterns. And then put the patterns into water for about 30 seconds. So it can make the hydrosol of water transfer decal paper start to dissolve. Immediately afterwards, you can slide the pattern apart from the base paper. And then it can transfer the pattern onto the objects. So far, it complete the water transfer process. Of course, some waterslide decals need to bake. For example, glass decals need to bake on oven for about 30 minutes at about 120℃. And ceramic decals need to bake on oven at 800C or 1300C.

How to use (apply) waterslide decal paper?

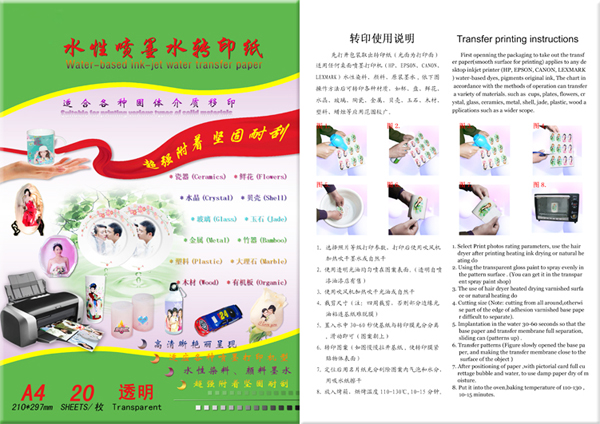

Below is the water transfer paper instructions tutorial:

1. Process flow of decal paper:

Inkjet waterslide decal paper instructions:

print pattern by inkjet printer——blow dry the ink or air dry——acrylic spray——blow dry the varnish or air dry——cut the pattern——put the waterslide decal into water——slide the base paper apart from pattern——transfer the pattern to object——scrape the graphic surface with a scraper to squeeze out the water——baking waterslide decals.

Laser water slide decal paper instructions:

print patterns by laser printer——cut the pattern——soak the water transfer decal into water——separate the base paper from pattern——transfer the pattern onto object——squeeze out the water——bake in the oven.

2. Two Follow-up instructions of water transfer paper:

(1) Bake the decal in oven, or air dry. For many items, such as ceramics, mugs, glass, it needs baking in the oven. It can increase the adhesion of the waterslide decal pattern. If apply for candles, wood or plastic, it does not need baking.

(2) Spray vanish after water transfer printing. For some other objects, such as wood furniture, helmet, plastic products, we usually spray vanish. Because it can protect the pattern, make it more durable and scratch resistant. Moreover, spraying varnish will not have a film effect. So it can improve product grade and value.

3. Baking Methods of Waterslide Decals

Due to the wide range of materials used in water transfer printing, the baking temperature varies. In principle, it cannot exceed the maximum temperature the object can withstand.

For example, it usually bake the mugs in the oven for 30 minutes at 160C. Bake the glass for 15 minutes at 120C. For metal products at about 100C. Bake the plastic items at about 50~70C. Helmet usually needs baking. For candles, it does not need baking, but only air dry.

Kind note: before baking in the oven, it must squeeze out the water. Otherwise, it is easy to produce bubbles. And it will influence the transfer effect of waterslie decal paper.

How to DIY use (apply) waterslide decal paper on plastic models?

The water slide decal paper has wide application for plastic models, such as airplane models, truck models, car models, etc. And many model players hope that they can make some water transfer decals with their own personal patterns in order to make the models more personal.

Now take the A4 inkjet water transfer paper as an example to introduce the detailed application tutorial of water decal paper. Of course,the application of laser water slide decal paper is similar. This kind of water slide decal paper is printable. And you can printe it by an ordinary household printer without any requirement for the printer. You can choose any pigment or dye ink.

Roughly talk about the application process of models decals:

- 1. Make your own water transfer decals pattern;

2. Export (Print) to water transfer paper;

3. Since the inkjet ink is water-based (in the case of water), we need to spray clear lacquer for the protective layer;

4. Soak the waterslide decal paper to separate the pattern from the paper and attach it onto the plastic models.

Water Transfer Paper Application Tutorial Introduction Begin

1. Introduction of materials and tools:

- Inkjet water transfer decal paper is divided into two types:

One is the white base(suitable for deep color or black objects);

Another is clear(suitable for white or light color objects).

About the protective paint, I use SANO brand AEROSOL PAINT (190 vanish). This spray paint is transparent and shiny. It is a quick-drying thermoplastic acrylic aerosol paint. And this paint has wide use in the coating of various metals, surface-treated wood, glass, plastic and other substrates. It can protect the pattern ink after printing the waterslide decal paper.

2. Now begin to make a water transfer pattern!!!

Firstly draw the water transfer pattern,size and color we want on the computer.

And then below are about waterslide decal paper printer settings.

Take EPSON R230 printer as an example. Choose the good quality photo rating (5760dpi HD print quality). And about the type of printing paper, choose “Epson high quality glossy paper”. Water transfer paper does not require special ink. Both pigment ink and dye ink are suitable.

3. Acrylic spray for waterslide paper

After the printing, it needs to print the spray paint onto the water transfer decal paper. The purpose of the varnish is to protect the printed ink, because generally the ink of the inkjet printer is water-based. It will turn off when dipping in water.So it needs to put on transparent paint to make a protective layer. We use the SANO brand vanish.

Kind note: it needs to spray the paint evenly.

After spraying, you can see that there is a layer of luster on the paper surface. Wait until dry after spraying. It can also use a hair dryer to “accelerate” (I do this).

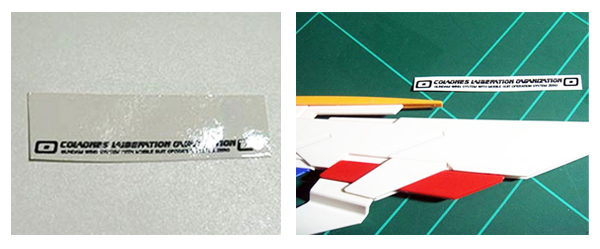

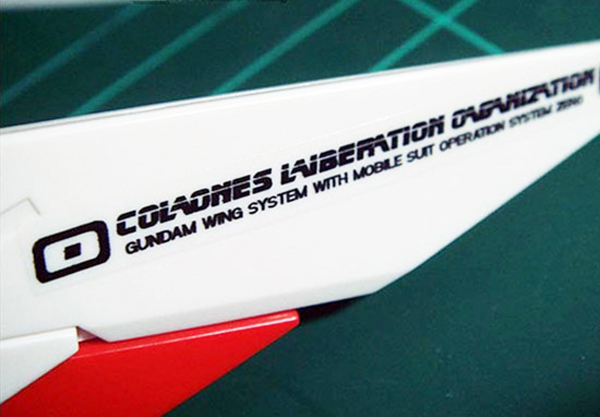

4. Apply the waterslide decal paper on models

Wait until dry completely. Cut the pattern to fit the size.

Then the operation step is the same as the water transfer printing we generally use. Soak the water transfer decals into the water, so that the pattern can separate from the base paper.

Paste the pattern onto the airplane model. Slowly push out bubbles and blisters until the pattern is smooth. Below is the water transfer paper application effect.

How to use waterslide decal paper on glass / ceramic mugs or bottles?

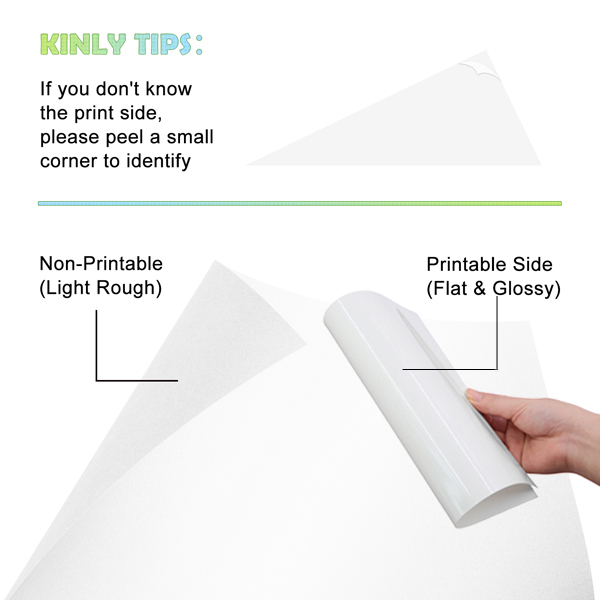

Firstly, before printing, it needs to distinguish the printing side and back side of water slide decal paper. Please check the below picture. The printing (printable) side of water transfer paper is glossy. But the back side of water decal paper is light rough & matte. Here use the transparent / clear water transfer paper.

Below are the detailed application of water slide decal paper on mugs:

- 1. Print the image on the printable side of water transfer paper with inkjet printer. And wait for it to dry completely.

- 2. Place the decal paper and acrylic spray in a well-ventilated space. Spray evenly on the image with acrylic spray for 3~4 times and then let it dry completely. Of course, it can use the hair dryer.

- 3. Cut the image ( Do not cut too close to the edge of the image, leave out about 0.08~0.12 inch of spacing).

- 4. Put the waterslide decals into water for about 10-~45 seconds.

- 5. Quickly apply it onto mugs, and slide the base paper apart from the pattern. And then remove air bubbles and excess water.

- 6. Put the ceramic mugs into oven for about 30 minutes at 160℃. If glass mugs or bottles, the baking time is about 15 minutes and temperature is at 120℃.

How to use waterslide decal paper on candles?

It’s easy to DIY use water transfer decal paper to make decals for candles. Not only creative, but also colorful. Because the candles are white colors, here use the transparent / clear water transfer paper.

- 1. Print the pattern on clear water slide decal paper with laser printer.

2. Spray paint on the waterslide decals evenly. Let the decal paper dry naturally, or use hair dryer.

3. Cut the pattern, and put it into water for about 20 seconds.

4. Stick the decals onto candle. And slide the base paper apart from pattern.

5. Then it finishes the water transfer printing process. And let the candles dry naturally. Different from mugs decals, it does not need baking in the oven.

Waterslide decal paper problems & troubleshooting:

- 1. The print pattern is not fine: The printing settings are not done properly. The printer paper type selection does not match.

- 2. Ink smudging when transferring patterns: after printing the pattern, no spray varnish. Of course, there is a kind of film free waterslide decal paper.

- 3. There are bubbles on the surface of the media after transferring the pattern: This is because it does not squeege the moisture in the transfer film during water transfer printing.

- 4. After overcoat, the surface is uneven: it is because of uneven varnish spraying. The water transfer film is slightly uneven in thickness.

- 5. After transferring the pattern, there will be discoloration within a few days: This is because after printing the pattern, then spray the varnish before the ink is dry.

- 6. After apply water transfer paper, the pattern color will fade after being exposed to outdoor ultraviolet light for one month: because inkjet decal paper uses water-based pigment ink. Water and dye molecules quickly decompose under ultraviolet light.

Precautions When Apply Water Transfer Decal Paper

- Before printing:

- (1) Please keep the water transfer paper under relatively stable environmental conditions. The temperature difference should not be too large. Avoid high temperature and direct sunlight. The best printing environment for water transfer paper is a relatively stable state with a temperature of 22°C and a humidity of 55%. It is best to keep the workshop constant temperature and humidity. Keep the ground and air dry. It is recommended to lay the water slide decal paper flat. Otherwise, the paper will bend during printing. At the same time, it will also affect the printing effect.

(2) It should put the decal paper into the printing workshop before printing. So the paper can adapt to the environment. Wait for the water slide paper to stabilize before printing. When printing very precise or high-grade decal paper containing gold, it is best to finish it in the same shift in the same environment to reduce unnecessary losses.

- (3) It must clean the surface of the object. It is best to use tape to stick the dust off.

- When printing:

(1)When opening the package, pay attention to the front and back of the water transfer paper. The cover of the package is the front and the printing side.

(2) Avoid scratches or stains on the surface coating of the decal paper.

(3) Use clean warm water (approximately 25°C) when apply the waterslide decal paper. It is especially important to use warm water in winter. Note that the soaking time cannot be too long. Usually 20 seconds is enough until you can slide the pattern apart from the base paper.

- After printing:

(1) Do not touch the pattern before the ink is completely dry. Place the water transfer paper horizontally to fully dry (or blow dry with a hair dryer).

(2) It must fully remove moisture and bubbles before baking the water transfer decals. Otherwise, it will affect the clarity of the pattern.

How to make waterslide decal paper?

1. Manufacturing process of water transfer paper.

Below figure is a schematic diagram of the production process of water transfer paper.

(1)Firstly, coating preparation: including primer coating, top coating, starch glue coating, dextrin glue coating and back coating coating. After complete preparation, put it in the storage tank for later use;

(2) Secondly, one-time coating and drying: coat the base paint on the upper surface of the base paper and drying. It forms a first coating layer of decal paper;

(3) Thirdly, secondary coating and drying: coat the top paint on the upper surface of the first coating layer and drying. It forms the second coating layer of water slide decal paper;

(4) Fourthly, three coating and drying: coat the starch glue on the upper surface of the second coating layer and drying. It forms the third coating layer of water transfer paper;

(5) Fifthly, four times of coating and drying: coat the dextrin glue paint on the upper surface of the third coating layer and drying. It forms the fourth coating layer of waterslide transfer paper;

(6) Sixthly, five times of coating and drying: coat the back paint on the back of the base paper and drying. It forms a back coating layer of decal paper;

(7) Then Calendering: calendering the waterslide decal paper after five times of coating and drying;

(8) Rolling, paper cutting and packaging.

2. what is waterslide decal paper made of?

Firstly, the formula of the primer coating of water transfer paper is as follows:

20~25 parts of water, 20~25 parts of porcelain clay, 0.1~0.2 parts of dispersant, 80~100 parts of calcium carbonate, 14~16 parts of carboxymethyl styrene butadiene latex, 0.3~1 parts of sodium carboxymethyl cellulose, calcium stearate 0.5~0.8 parts of lubricant, 0.05~0.07 parts of defoamer, 0.02~0.03 parts of caustic soda;

Secondly, the top coating formulation of waterslide decal paper is as follows:

50~60 parts of water, 20~25 parts of porcelain clay, 0.05~0.08 parts of dispersant, 40~50 parts of calcium carbonate, 13~15 parts of carboxymethyl styrene butadiene latex, 0.1~0.3 parts of sodium carboxymethyl cellulose, calcium stearate 0.8~1 part of lubricant, 0.03~0.05 part of defoamer, 0.015~0.02 part of caustic soda.

In addition, the preparation methods of top coating or base coating are below:

Use a disperser to mix water, china clay, dispersant and calcium carbonate evenly. Afterwards, continue to stir and add carboxymethyl styrene butadiene latex, sodium carboxymethyl cellulose, calcium stearate lubricant, defoamer and caustic soda. Until it is evenly stirred. The stirring speed is 1200-3000r/min. Then put it into the reserve tank for standby.

3. Adjustment of various indicators of water transfer paper。

In addition, if adjust the proportions of porcelain clay and calcium carbonate in the primer and topcoat separately, it can improve the whiteness, opacity, water permeability and gloss of the waterslide decal paper.

For example, when the minimum amount of porcelain clay in the primer coating is 20 parts and calcium carbonate is 80 parts, the whiteness of the first coating layer is the worst, the gloss is the lowest, and the water permeability is better. Therefore, it can increase the release speed of the waterslide decal paper.

Performance requirements of water transfer paper

Due to the needs of coating film and subsequent printing and transfer, the waterslide decal paper must have sufficient strength, stiffness, smoothness and dimensional stability and other indicators. It is generally made of pure wood pulp fiber. If you want to print very fine patterns, or in very demanding occasions, it generally uses coated base paper to produce water transfer paper.

1. Water slide decal paper requires good dimensional stability:

When printing graphics, water transfer paper needs to be chromatic printing. Poor dimensional stability will lead to inaccurate registration. If a layer of back coating is added to the back of the base paper, the paper will shrink evenly during drying. This will not produce curling phenomenon, which is conducive to color printing.

2. Water decal paper requires higher smoothness and stiffness:

Most water transfer papers are cut into flat decal paper sheets. After printing, it requires high smoothness and stiffness of the base paper. When feeding sheet paper, the stiffness of the paper must be high enough. In this way, no folding occurs when a single sheet is fed. Effective calendering during the experiment can improve the smoothness of the finished waterslide decal paper.

3. Waterslide Transfer Paper Requires Excellent Release Performance

When using decal transfer paper, the graphics must be separated from the base paper smoothly within 60s. Only use a little force to slide instead of tearing apart. That is, the release time of the water slide decal paper needs to be short. It requires good slippage and no residue after the film is removed. The release time of good quality water transfer paper can usually be in 30 seconds.

4. Decal Paper Requires Suitable Glue Coating Method

Since the graphic layer of the water transfer paper does not seep water, water can only enter from the back of the decal paper when soaking. It require no glue coated on the back of the base paper. The purpose of front glue-coating is to prevent the hydrosol layer from penetrating into the paper quickly. The water-soluble glue layer is formed on the surface of the base paper, and the dissolving speed of the water-soluble glue layer that plays a role of transfer is very slow. In this way, it penetrates into the inside of the paper and combines with the fibers, making water less permeable. Therefore, it only coat glue on surface of the base paper, not in the pulp.

5. Waterslide decal paper requires high gloss

Although the glossiness of water transfer paper has nothing to do with its performance and will not affect the release time of the finished paper, it has a lot to do with the quality of the pattern. The higher the gloss of waterslide decal paper, the more beautiful its appearance. Then the colors of the printed patterns become brighter and brighter.

6. Decal transfer paper requires the uniformity of fiber structure

When using waterslide decal paper, the pattern must be separated from the bottom paper. The key to separation is the water-soluble glue layer. If the coating amount of the water-soluble adhesive layer is not uniform, the pattern and the base paper will not be separated uniformly within the specified time during use. The uneven fiber structure of the base paper will cause uneven absorption of the paint. As a result, the coating amount of the water-soluble glue layer is uneven. Therefore, the water transfer paper needs to have a good uniformity.

7. Water transfer decal paper requires suitable moisture content

In order to facilitate the production of waterslide decal paper, it is generally better to keep the moisture of water slide decal paper paper at 4% to 5% during storage. But the moisture content of the base paper must be even. If the moisture content of the base paper is not uniform, the surface of the coated finished paper will be uneven during the production of water transfer paper.

FAQ of Water Transfer Decal Paper

Q1: where can i buy waterslide decal paper?

A1: You can buy the water transfer paper directly on our website. And you can order 20 sheets for test.

Q2: is water slide decal paper permanent?

A2: the adhesion of decal paper is determined by product material and apply process. Most water transfer paper pattern is not permanent. For example, temporary tattoo made by decal paper only lasts for several days. But ceramics baking at 1300C has permanent effect. And if want to increase adhesion, you can baking the objects in oven, or spray vanish on pattern after application.

Q3: is waterslide paper waterproof?

A3: No. Waterslide paper is very sensitive to water, because the paper has water-soluble glue. If the water transfer paper gets damp, it will seriously affect the printing effect. Therefore, the paper must be sealed well when using and storing. Pay attention to air humidity and ventilate well.

Q4: what kind of printer and ink do you use for waterslide paper?

A4: the inkjet decal paper is suitable for any inkjet printers and ordinary water-based pigment ink & dye Ink.

Laserjet decal paper is suitable for any laser printer.

Q5: is waterslide paper the same as tattoo paper?

A5: yes. The temporary tattoo paper is also waterslide decal paper.

Q6: how to distinguish the printing side and the back side of the water transfer paper?

A6: The glossy side is the printing side and the matte side is the back side.

Q7: Which varnish to use after apply waterslide decal paper?

A7: varnish used in water transfer printing: automatic spray paint, self-spray transparent varnish, a light protection transparent paint, acrylic aerosol paint. Varnish is widely used in furniture, helmets and other materials surface light protection.

Main function: After printing the picture, spray evenly on the pattern surface. Play the role of protecting the pattern.

Q8: what’s the difference between waterslide decal paper and hydrographic film?

A8: Water transfer paper is only used for objects with regular surfaces. But the hydrographic film can be used not only on regular surfaces, but also on irregular surfaces.

Showing all 11 results