With the increasing development of industrial mechanization, customers have more and more requirements for different conveyor belts. As a result, the processing methods of the conveyor belt have become diversified: adding guide bars, adding corrugated sidewall, adding baffles, punching and so on. In view of these, here introduce to you the advantages and maintenance precautions of cleated conveyor belt.

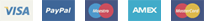

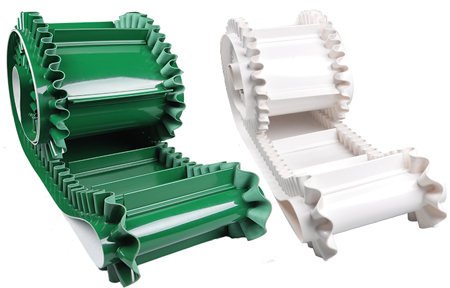

The cleated conveyor belt composes of base belt, baffle and skirt, and its advantages are as follows:

- High-strength and wear-resistant base belt, with good lateral stability and longitudinal flexibility.

- The conveyor angle of the cleated conveyor belt reaches 30 to 90 degrees.

- The cleated conveyor belt can effectively prevent materials from falling.

- Cleated conveyor belt has a large conveying capacity and a high lifting height.

- The cleated conveyor belt occupies a small space and has a wide range of use. Easy installation, simple maintenance and low investment.

Next is the maintenance precautions of the cleated conveyor belt:

- The running speed of the conveyor belt should generally not be greater than 2.5 m/s. For materials with large lumpiness and high abrasiveness, it should use low speed as much as possible.

- During storage, the skirt baffle conveyor belt must be placed in rolls and cannot be folded. It should be flipped every quarter during the placement period.

- The temperature of the warehouse where the cleated conveyor belt is stored should be between 18-40℃. The relative humidity should be between 50~80%.

- It is necessary to prevent the load start of the cleated sidewall conveyor belt. When deviation occurs, it needs take corrective measures in time.