Description

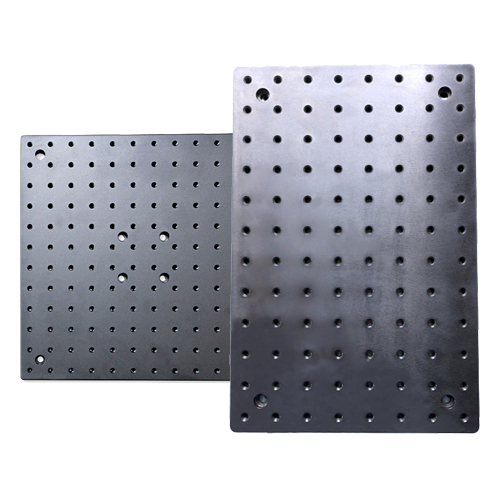

Optical breadboard is a common light path fixed base. It is also an economical choice to quickly build a small optical path. The main application of aluminum breadboard is to build compact optical systems. There are standard M6 thread hole on the surface. It can fix the optomechanical parts by M6 screws. In addition, the aluminum optical breadboard metal plate uses black anodizing. So it can avoid specular reflection of stray light in the experiment.

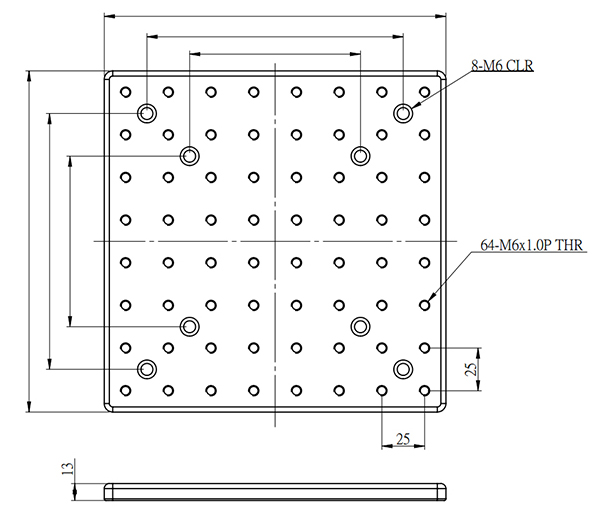

In addition, there are standard M6 thread through holes on the breadboard aluminum plate. The hole spacing is 25 mm. So it is convenient for customers to install devices from both sides. Moreover, the countersunk mounting holes can be used to install vibration isolation rubber bases or other mounting bases. It can install the solid aluminum breadboard on the surface of the optical table. When the center of the breadboard has a large load-bearing capacity, adding a mounting base can ensure the rigidity of the breadboard surface. Then it can reduce deformation.

The Specification of Solid Aluminum breadboard Plate

Product name: solid non-magnetic metric aluminum breadboard;

Material: 7075-T6 aluminum alloy;

Surface treatment: black anodized;

Breadboard plate thickness: 13mm;

Flatness (full plane): ±0.15 mm;

M6 thread through holes on the surface. At the same time, the hole spacing is 25 mm;

There are countersunk mounting holes around and in the center of the breadboard (if length<450mm, there are 4 countersunk mounting holes; if length>450mm, there are 8 holes)

A variety of sizes & customization are available;

Application: act as a base plate for the optical experimental platform;

| Optical Breadboard Model | Material | Size (mm) (L*W) | Thicknes (mm) | Thread Hole | Hole Spacing | Weight (kg) |

| HY-1020-13 | Aluminum Alloy | 100*200 | 13 | M6 | 25*25 | 0.8 |

| HY-1515-13 | Aluminum Alloy | 150*150 | 13 | M6 | 25*25 | 0.8 |

| HY-1520-13 | Aluminum Alloy | 150*200 | 13 | M6 | 25*25 | 1.3 |

| HY-1530-13 | Aluminum Alloy | 150*300 | 13 | M6 | 25*25 | 1.5 |

| HY-2020-13 | Aluminum Alloy | 200*200 | 13 | M6 | 25*25 | 1.4 |

| HY-2025-13 | Aluminum Alloy | 200*250 | 13 | M6 | 25*25 | 1.7 |

| HY-2030-13 | Aluminum Alloy | 200*300 | 13 | M6 | 25*25 | 2 |

| HY-2530-13 | Aluminum Alloy | 250*300 | 13 | M6 | 25*25 | 2.5 |

| HY-3030-13 | Aluminum Alloy | 300*300 | 13 | M6 | 25*25 | 3 |

| HY-3045-13 | Aluminum Alloy | 300*450 | 13 | M6 | 25*25 | 4.5 |

| HY-3060-13 | Aluminum Alloy | 300*600 | 13 | M6 | 25*25 | 6 |

| HY-4060-13 | Aluminum Alloy | 400*600 | 13 | M6 | 25*25 | 7.5 |

| HY-4560-13 | Aluminum Alloy | 450*600 | 13 | M6 | 25*25 | 9 |

| HY-6060-13 | Aluminum Alloy | 600*600 | 13 | M6 | 25*25 | 12 |

| HY-6090-13 | Aluminum Alloy | 600*900 | 13 | M6 | 25*25 | 18 |

| HY-2020-13M | Alloy Steel | 200*200 | 13 | M6 | 25*25 | 4 |

| HY-2025-13M | Alloy Steel | 200*250 | 13 | M6 | 25*25 | 5 |

| HY-2030-13M | Alloy Steel | 200*300 | 13 | M6 | 25*25 | 6 |

| HY-2530-13M | Alloy Steel | 250*300 | 13 | M6 | 25*25 | 7.5 |

| HY-3045-13M | Alloy Steel | 300*450 | 13 | M6 | 25*25 | 13.6 |

| HY-4560-13M | Alloy Steel | 450*600 | 13 | M6 | 25*25 | 27.3 |

| HY-6060-13M | Alloy Steel | 600*600 | 13 | M6 | 25*25 | 36.5 |

Features of Optical Breadboard Aluminum Plate

1. Firstly use high-quality solid aluminum alloy for finishing. Light weight and easy to move. Moreover, it maintains sufficient hardness and is not easily deformed.

2. Secondly, M6 standard thread holes are convenient for fixing various components, such as optical mount, translation stage, optical bench, etc. In addition, hole spacing is 25mm.

3. It adapts the black anodizing surface treatment. Thus, it can suppress the reflection to the maximum extent. The surface is not only smooth and flat, but also beautiful and durable.

4. There are counterbores on the aluminum breadboard. So it will not affect the installation surface in any customer application.

5. For vacuum applications, we recommend using non-anodized breadboards.

6. The main purpose is to build light paths or fix instruments in the laboratory. In addition, it can also act as a workbench in the industrial field.

Installation Options for Aluminum Breadboard

-

1. Vertical installation

Firstly, it installs the optical aluminum breadboard vertically through various 90-degree mounting plates. We recommend using the device in the picture for installation. In the picture, it uses two VB01 vertical brackets to install on the MB12 breadboard. Smaller breadboard plate can use AB90, AP90 or AP90L right-angle brackets.

2. Vibration isolation bracket

It can install aluminum breadboard plate on a set of vibration isolation brackets. These polyester rubber mounting brackets can isolate the breadboard from the mounting surface.

3. Use adjustable feet to increase height

Firstly, use a set of φ1.5 inch extension rods to raise the breadboard from the work surface. The picture shows the use of four P6 mounting posts to raise the MB1824 breadboard. Each post is connected with a BMF4 adjustable self-leveling mounting foot. Self-level installation feet have rubber pads. It can adjust the height by thread.

4. Use non-adjustable base post for heightening

The picture shows the fixed aluminum breadboard mounting option. Firstly, it uses the base type φ1.5 inch post to install on the optical table. The picture shows the MB1824 breadboard plate. It uses four P6 mounting posts to lift from the surface of the optical table. Moreover, each post is fixed with a PB4 base adapter and PF175 clamp.

5. Breadboard enclosure system

It can add a cover to the aluminum optical breadboard. So it can shield the equipment from light and dust. Several plexiglass and standard black cover are available. The front panel of the cover shown in the picture has been removed for easy operation.

6. Breadboard mounting bracket

The PSY321(/S) breadboard bracket can firmly install the breadboard on the φ1.5-inch post. Each bracket can support any aluminum breadboard with a maximum size of 12 inches * 12 inches (300mm*300mm). The maximum load capacity is 20KG.

Reviews

There are no reviews yet.